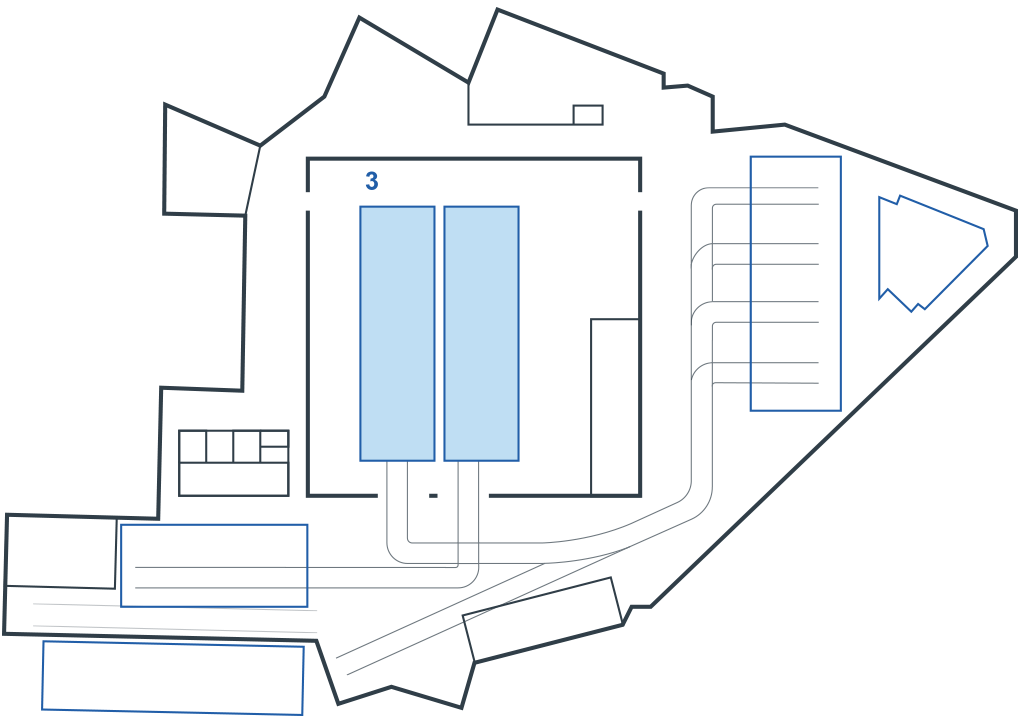

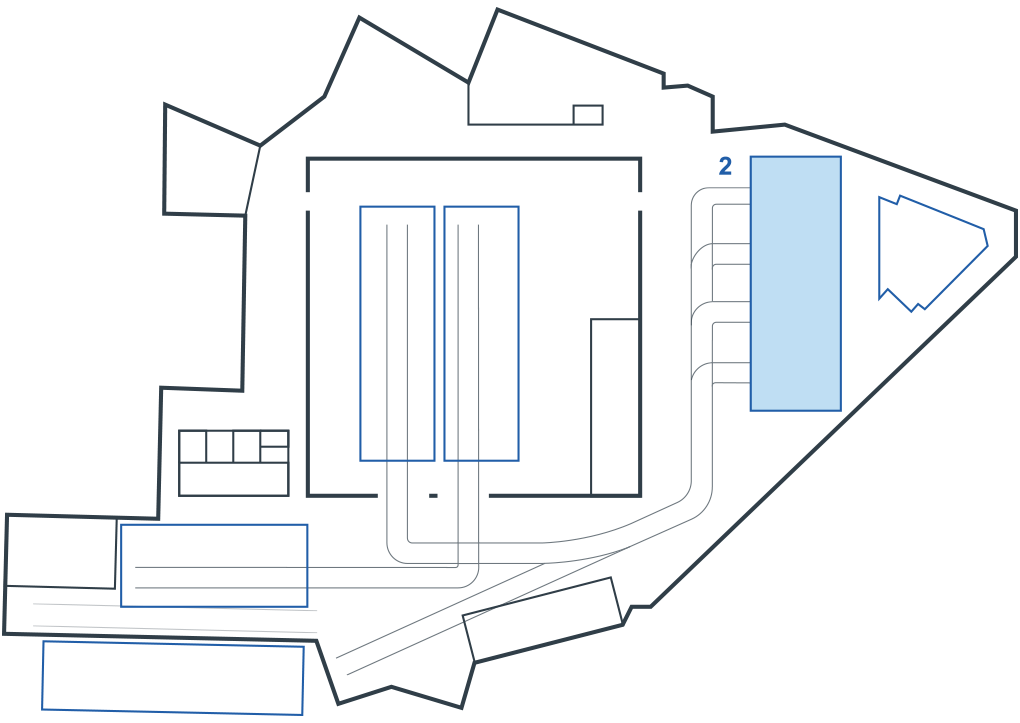

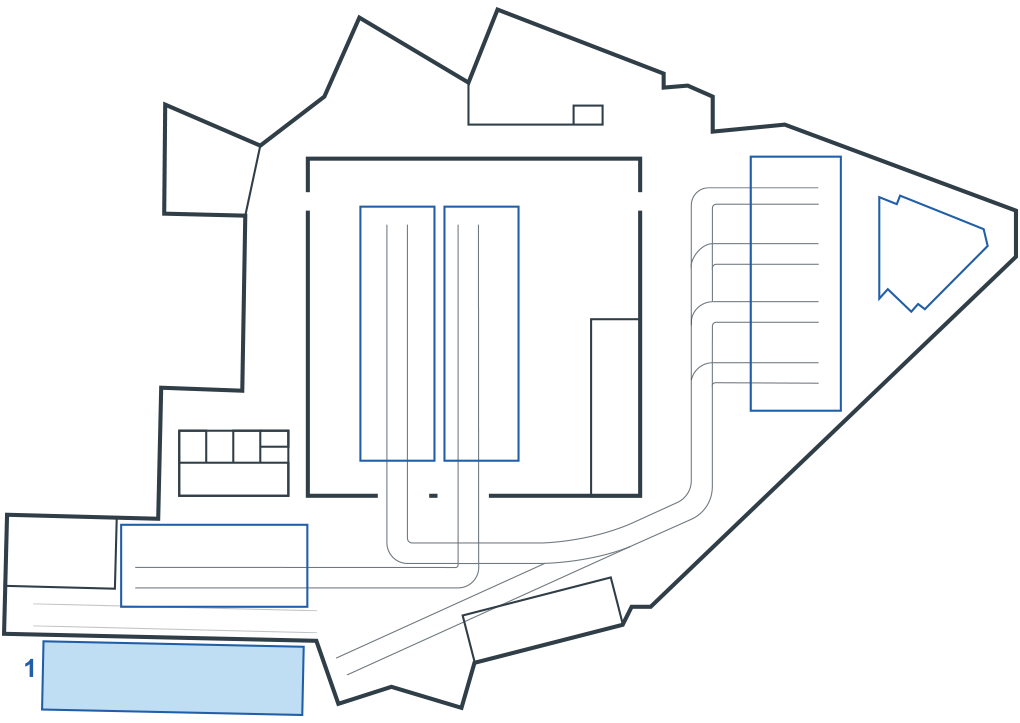

Covered area

The covered area is divided into six 150 m wide spans equipped with 22 bridge cranes with lifting capacities ranging from 10 to 100 tonnes, as well as with other lifting means.

- 2 spans 25 x 150 m, 8 bridge cranes max. capacity 100 tonnes, useful height 20 m

- 1 span 26 x 150 m, no. 2 10-tonne bridge cranes, useful height 8 m

- 3 spans 20 x 150 m, no. 12 overhead cranes max. 10 tonne, useful height 8 m

- Transfer trolleys max 25 tonne capacity for product transfer

- Sheet and section bar treatment plant, equipped with rectifier and automatic

- 6-turbine rotary blasting machine, pre-heating system, automatic painting system, motorized rollers for sheet feeding

- Oxyfuel welding/cutting department with automatic pantographs for oxyacetylene and plasma cutting

- Welding department with automatic machines for submerged arc welding

- Mechanical department with 2 numerically controlled “Cerruti” boring machines

- Light metalworking departments

- Reparto meccanica con n. 2 alesatrici “Cerruti” a controllo numerico

- Heavy metalworking and boiler departments, with bending machine for up to 80 mm thick and 3,500 mm long sheets

- Magnetic cranes for sheet metal handling

- 700 square meter internal warehouse

- 450 square meters of design office space